Basic knowledge of Orifice Meter.

Basically, an Orifice meter is referred as a type of flow meter that uses differential pressure measurement techniques and this helps to get discharge rate as well as calculate the flow rate.

In short, Orifice meters is a device to measure the flow rate or discharge rate of any fluid. Oficemeter is used mainly in robust applications and an Orifice meter works based on the differential measurement technique.

INDEX

- What is the Orifice Meter?

- Orifice Flange Explained (ASME B16.36)

- Construction of an Orifice Meter.

- Basic Working Principle of an Orifice Meter.

- What is the purpose of orifice?

- Why orifice meter is better than Venturimeter?

- Applications of Orifice Meter

- Why orifice meter is better than Venturimeter?

- Which is the main advantage of orifice meter?

- Where is orifice meter used?

- What is Venturimeter?

- What type of materials are required for orifice plates are?

- What are the difference between Orifice Meter and Venturimeter?

1. What is the Orifice Meter?

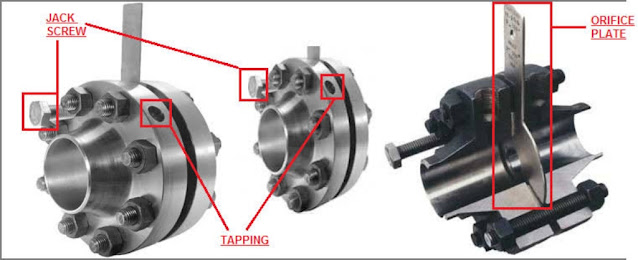

- An orifice meter is a piece of equipment used to measure the flow rate of a gas or a fluid. It mainly consists of an orifice plate, an orifice plate housing, and a meter tube.

- The Orifice Flange is used to measure the flow of product through the piping system. When the Orifice Plate is installed there is a restriction of flow creating a differential pressure and this is used to measure the flow rate of liquids, steam or gases.

- An orifice meter consists of an orifice plate, a holding device, upstream downstream meter piping, and pressure taps.

2. Orifice Flange Explained (ASME B16.36).

- An Orifice Flange is used in combination with orifice meters to measure the flow rate of oil, gas and other liquids conveyed by the pipeline. Orifice flanges are manufactured to ASME B16.36 in multiple sizes and, material grades.

- Orifice flanges are available in all ASTM forged grades (ASTM A105, ASTM A350, ASTM A694, ASTM 182 respectively for carbon, alloy and, stainless steel flanges), dimensions (combinations of nominal sizes and pressure ratings) and, in socket weld, threaded or weld neck shape (WN is the most used).

It is typically made of carbon steel, and the main components of the device are:

- Inlet Section – a linear segment extending from the device and acts as an end connection for the fluid flowing inside.

- Outlet Section – also a linear segment similar to the inlet section where the pressure of the gas or fluid discharged is determined.

- Orifice Plate – present between the outlet and inlet segments and used to generate a pressure drop which enables the measurement of the flow rate.

- Flow Conditioner – installed in the inlet section of the meter tube and is used to enhance linear flow in the inlet section of the meter tube.

4.Basic Working Principle of an Orifice Meter?

It works on the Differential Pressure Measurement principle.

• The liquid or gas whose flow rate is to be determined is passed through the orifice plate.

• This creates a pressure drop across the orifice plate which varies with the flow rate, resulting in a differential pressure between the outlet and inlet segments.

• This pressure drop is measured and is used to calculate the flow rate of the fluid or gas.

• Orifices are used as fixed throttles that generate head loss. The head loss caused by an orifice can be used to determine the volume or mass rate of flow during flow metering. Orifices used in flow metering are preferably designed as a standard orifice.

6.Why orifice meter is better than Venturimeter?

• The primary difference between a venturimeter and an orifice meter can be that the venturimeter is inflexible with the change in flow rate whereas, in the orifice meter, the orifice plate can conveniently change as per the different flow rates. Thus, is one significant difference between the two instruments

7.Applications of Orifice Meter

• It is used to measure the flow rate of fluids in their single state (i.e. gaseous state or liquid state).

• It can also be used to measure the flow rate of fluids in a mixed state (both gaseous and liquid states) such as, wet steam, or natural gas with water.

It is utilized in the following industries:

• Water treatment plants

• Natural gas industries

• Refineries

• Petrochemical plants

Listed below are the two primary uses of an orifice meter:

8.Why orifice meter is better than Venturimeter?

• The primary difference between a venturimeter and an orifice meter can be that the venturimeter is inflexible with the change in flow rate whereas, in the orifice meter, the orifice plate can conveniently change as per the different flow rates. Thus, is one significant difference between the two instruments

9.Which is the main advantage of orifice meter?

• Advantages of Orifice meter:

The orifice meter can be easily maintained. Measures a wide range of flows. They have a simple construction. They have easily fitted between the flanges.

- It is cost-effective and quite easy to use.

- It occupies less space, making it ideal for space-constrained applications.

- It can also be used to determine flow rates in large pipes.

- It can be installed in the horizontal or vertical positions.

10.Where is orifice meter used?

11. What is Venturimeter?

Volumatricmeter is a discharge measuring device, it measures

volumetric flow.

Here, You may ask what is volumetric flow?

So, volumetric flow is the amount of the fluid flowing or volume of fluid flowing through the media per unit of time. In short, the volume of the flowing fluid per unit of time.

12.What type of materials are required for orifice plates are?

13.What are the difference between Orifice Meter and Venturimeter?

Welcome to Our Blog Active Piping Knowledge.

I am Afzal an experienced piping engineer from the last 8 years. Through this platform, I will share my experiences and knowledge with you in an innovative way. So be with me for the next couple of years!

Comments

Post a Comment