Piping Reducer, Eccentric & Concentric Reducer.

Basic Details of Piping Reducer.

A pipe reducer is a pipe fitting that connects a larger pipe to a smaller pipe.

INDEX:-

- What is Piping Reducer?

- How many types of Reducer?

- What is Concentric Reducer ?

- What is Eccentric Reducer?

- What is the application of Concentric & Eccentric Reducer?

- Eccentric Reducer Installation?

- Types of Piping Reducers based on End Connection?

- Pipe Reducer Fitting Dimension?

- Information about how to purchase Reducer details.

What is Piping Reducer?

- A pipe reducer is a pipe fitting that connects a larger pipe to a smaller pipe.

- A pipe reducer is a pipe fitting that reduces the nominal bore from a bigger inner diameter to a smaller inner diameter.

- A reducer allows for a change in pipe size to meet hydraulic flow requirements of the system, or to adapt to existing piping of a different size.

- A reduces the size of the pipe in the pipe system, from one size to another.

- Pipe reducers may frequently be used to connect pipes of different sizes.

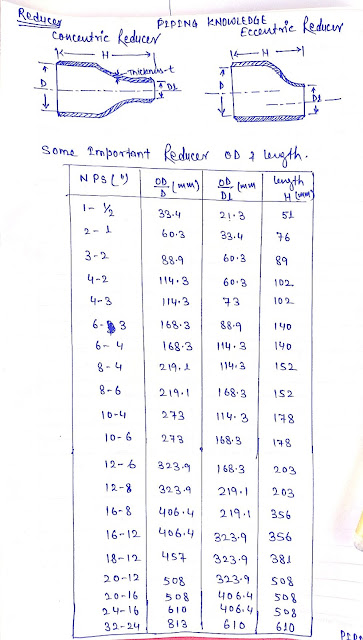

2. How many types of Reducer?

There are two main types of reducer:

- Concentric reducers

- Eccentric reducers

3. What is Concentric Reducer ?

- A concentric reducer is used to join pipe sections or tube sections on the same axis. The concentric reducer is cone-shaped, and is used when there is a shift in diameter between pipes.

- Concentric Reducers are used to join pipe or tube sections of different diameters on the same axis.

- They provide an in-line conical transition between pressurized pipes of differing diameters.

- Thus, concentric reducers connect pipes of unequal size but have a common centerline.

4. What is Eccentric Reducer?

- Eccentric reducers are more often used when the pipework lays on a pipe rack. Because of the flat side, aligning and securely mounting the pipes to the rack is easier.

- Those reducers also come in handy where there is a pump installed in liquid transporting systems. To avoid cavitation, the pipework is connected to the pump via an eccentric reducer that has its flat side facing up.

- This prevents the forming of bubbles and limits the chance of damaging the propellers inside the pump because of the cavitation phenomenon.

- Eccentric Reducer the decrease of the pipe size is achieved by decreasing the diameter of the fitting at a constant rate over a specified length, maintaining one side of the fitting horizontally.

- An eccentric pipe reducer fitting is manufactured with the smaller outlet off center to the larger end, which allows it to align with only one side of the inlet.

5. What is the application of Concentric & Eccentric Reducer?

- A reducer fitting is typically used in pump station pipe work to reduce the size of the suction pipe to match the size of the pump suction end flange.

- Reducer fittings used in pump inlet.

- Used to increase size of the line to a larger diameter. The bell is on the smaller end. Used to decrease the size of the line to a smaller diameter.

Concentric Reducer

- Concentric reducers will change kindly between the pump and piping.

- These reducers help to convey slurries and abrasive fluids.

- These reducers are useful to use in operations where corrosion is present.

- These reducers are beneficial to use where different ratings and to wear protection is required in conveying between flanges or pipe .

- Concentric reducers are perfectly suitable to use in the exclusion of the pump.

- Pump discharge alwasy use in Concentric Reducer.

Eccentric Reducer

- This type of reducer helps to connect big pipes with small pipes.

- These reducers decrease noise and vibration.

- It requires minimum setting up space.

- It also absorbs noise which is created by pipe wall and fluid tolerated.

- It has minimum turbulence entrapment.

- This type of reducer is utilized with the flat side up in pump pressure to minimize cavitation.

- Pump Suction alwasy use Eccentric Reducer.

6. Eccentric Reducer Installation

- Eccentric reducer user has the option of orienting the flat side top or bottom.

- Usually, for horizontal lines, eccentric reducers are oriented with either the flat side up or down, and the same with deviation is mentioned in isometric.

- Normally eccentric reducers with the flat side down because maintain the bottom level are preferred for following cases on horizontal lines:

- On Sleepers and Pipe rack to maintain same BOP for supporting and Alignment.

- On lines requiring gravity flow on the pump suction line which handles slurry that one also require for flat on bottom.

- Control valve station area eccentric reducer with flat side down is required to get a constant flow through the control valve with less flow disruptions in detail.

- In horizontal Gas steam, or vapour piping, eccentric reducer are required to be installed with flat side down which allows condensed water or fluid to drain at low point drip leg.

7.Types of Piping Reducers based on End Connection?

Some important type of end connection pipe Reducer.

- But welded pipe Reducer.

- Socket welded pipe reducer.

- Screwed Welded pipe reducer.

- Flange pipe Reduce

8.Pipe Reducer Fitting Dimension?

- All dimensions for butt welded piping reducers are provided by ASME B 16.9.

9. Information about how to purchase Reducer details?

The following information should be important when you give the details on your suppliers

- Pipe Size and Outer diameter as per isometric.

- American standard (ASME B16.9).

- End connection (Welded/Screwed/Flanged, etc)

- Distance from end to end after Beveling.

- Material of construction details.

- Seamless or welded construction type.

- As per service and Corrosion allowance Pressure class and size of Isometric.

Comments

Post a Comment